Producción en serie rentable en metal y polimeros

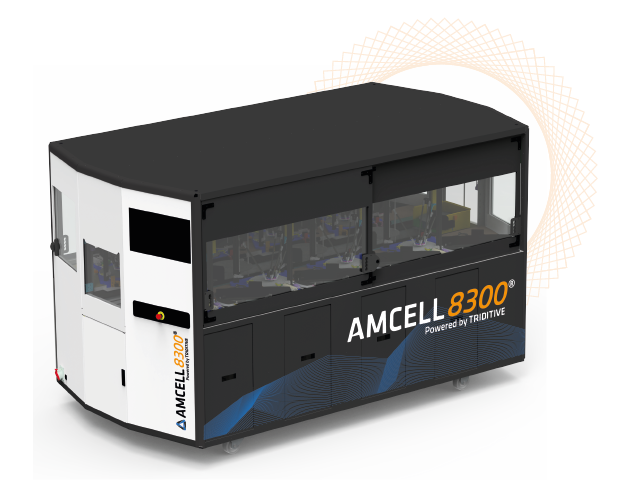

Amcell 8300®

AMCELL 8300® es una célula de fabricación aditiva automatizada para la producción en serie de piezas finales de alta complejidad y precisión, controlada por el software EVAM® para gestionar las órdenes de producción, el control durante el proceso y reducir los tiempos de inactividad de la máquina.

Las órdenes de fabricación, la supervisión del proceso, el control de la materia prima y el control ambiental inteligente son solo algunas de las características que hacen de AMCELL 8300® una verdadera plataforma para la producción en masa.

Piezas precisas y funcionales con AMCELL®

- Polimeros

- Materiales compuestos

- Metales

- Alta tolerancia

- Producción en serie

EVAM Software

- Control y monitorización centralizados

- Control inteligente de la materia prima

- Optimización de la producción

- Integración con impresora

- Simulación de fabricación

- Scheduling

- Conectividad con el taller

- Monitorización de la calidad y el proceso

- Trazabilidad

- Producción en serie

¿Te interesa la AMCELL 8300®?

AMCELL 8300® está diseñado y fabricado por Triditive. La fabricación aditiva automatizada es uno de esos cambios con el potencial de transformarlo todo. Una tecnología que permite escalar la producción exponencialmente.

Intelligent Automatic System

Permite la fabricación 24/7 de piezas funcionales.

Flujo de trabajo controlado por Software y monitorización del proceso

AMCELL 8300® incluye el software EVAM, la más avanzada solución para el control de la producción y la monitorización en remoto.

Calibración automática

Cada cabezal de impresión se calibra automáticamente antes de cada trabajo de impresión para garantizar la máxima calidad de la pieza final.

Automatización de impresión 3D

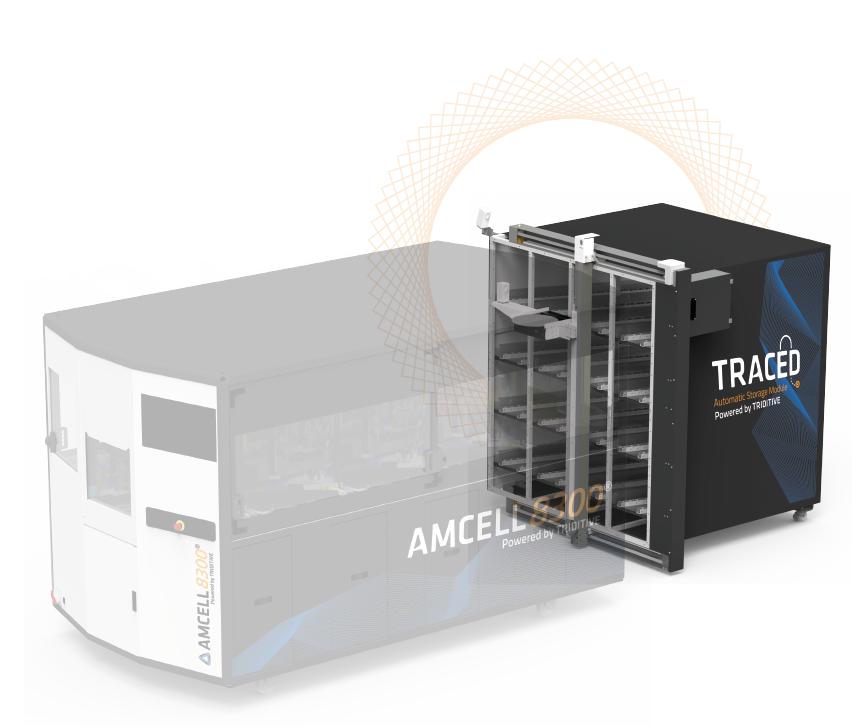

A medida que una pieza impresa es expulsada al módulo de almacenamiento automático, se carga una nueva plataforma, garantizando así una producción ininterrumpida 24/7.

Almacenamiento automático

Trazabilidad y almacenamiento automático de las piezas impresas.

AMCELL 8300 + TRACED

Nuestros materiales

Imprimimos en una amplia gama de materiales.

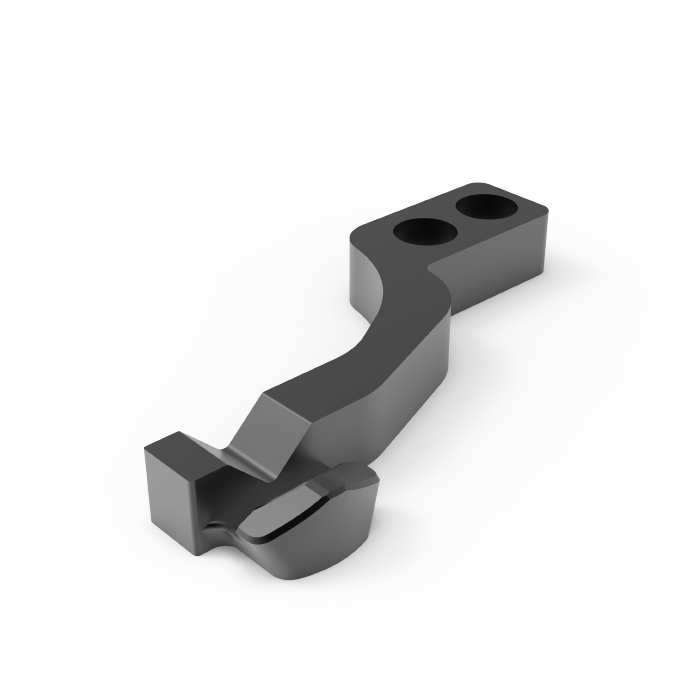

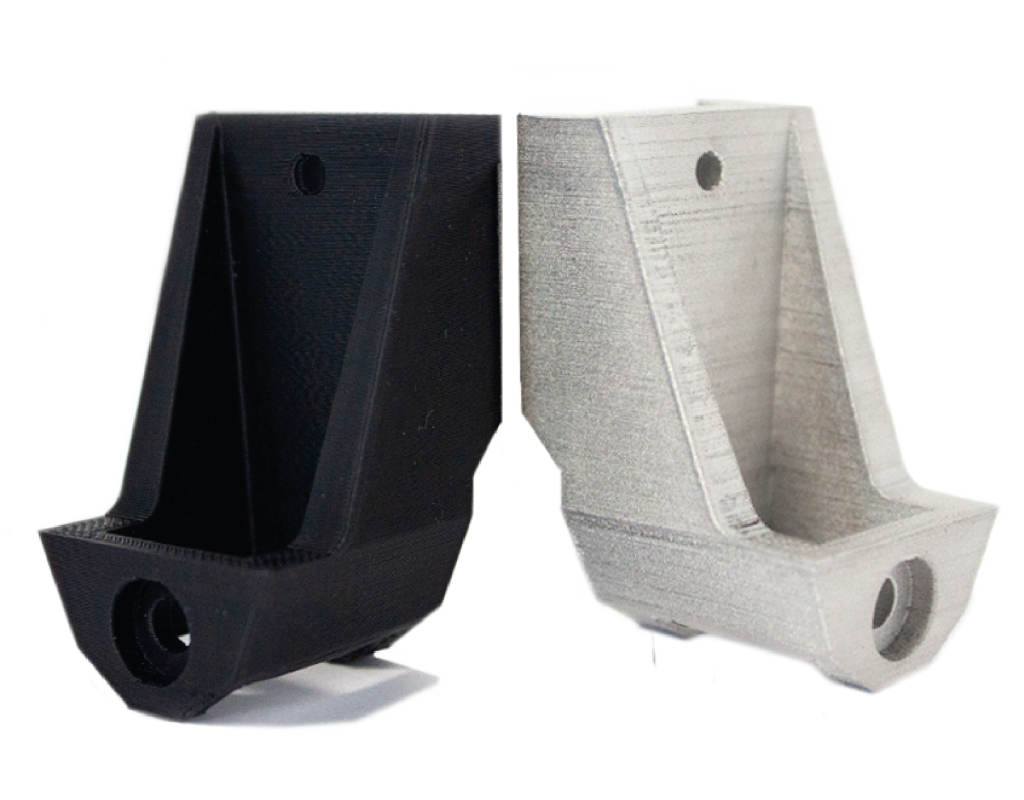

Metales

Una de las ventajas de la impresión 3D en metal es que tiene el potencial de ser más rentable, especialmente en volúmenes bajos de producción, para partes difícilmente mecanizables debido a su complejidad morfológica.

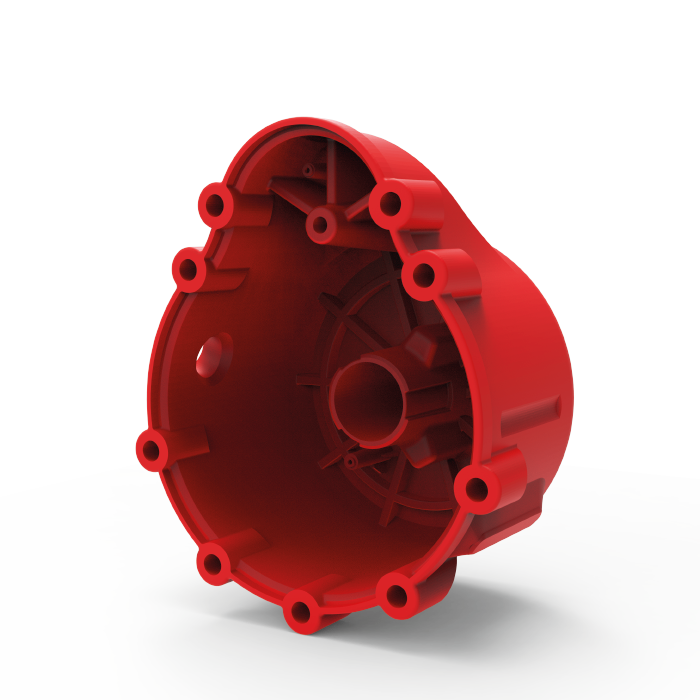

Polimeros

Podemos producir piezas en polímeros funcionales y complejas con la resistencia, la precisión dimensional y la calidad de acabado necesarias para una producción de gran volumen.

Materiales compuestos

Los materiales compuestos se utilizan normalmente para mejorar la resistencia, la rigidez, la resistencia al calor y la durabilidad de las piezas impresas en 3D

Tecnología AMD® para metales

Automated Multimaterial Deposition® (AMD) es un proceso de fabricación aditiva. La principal innovación que incorpora nuestra tecnología es la automatización y su capacidad para fabricar piezas en polímeros, materiales compuestos y metales, incluso al mismo tiempo.

Especificaciones técnicas

- Tasa de producción: 2 Tons polymer/year - 8 Tons metal/year

- Altura máxima de impresión: 350mm

- Superficie máxima de impresión: 300mm

- Sistema extrusor: Direct

- Diametro de boquilla: 0.4 - 0.8 mm

- altura mínima de capa:30 μm

- Número de robots: 8 (personalizable)

- Cámara de impresión: Calefacción con control de temperatura, Sistema de filtrado.

- Dimensiones exteriores: 3,4 x 2 x 2 m.

- Peso sin carga: 1300kg.

- Con carga 1700kg.

Plataformas de fabricación

- Sistema de cambio de plataforma: Automático

- Sistema de eyección: Sistema STEP

- Plataforma de impresión: Heated up to 150 ªC

- Material de la plataforma de impresión: Vidrio templado (personalizable)

- Calibración de la plataforma de construcción : Automático

- Almacenamiento de piezas finales: Automático TRACED

Materiales de fabricación

Polimeros: ABS, ASA, CPE, HIPS, IGLIDUR I150-PF. PA,PC, PETG, PLA, TPU, VYNIL.

Compuestos: PA+ARAMIDE, PA+CF, PC+ABS, PC+PBT

Metals: SS316L, SS17-4PH, INCONEL, TITANIUM.

Nuestras Soluciones

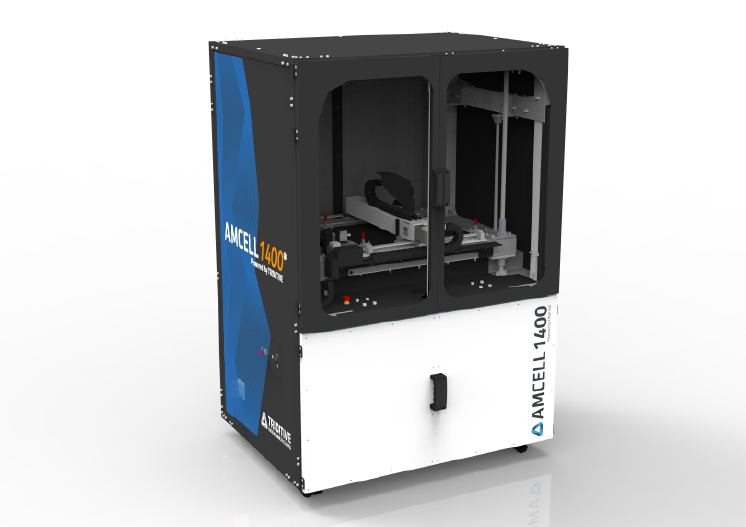

Amcell 1400

AMCELL 1400® hace que la fabricación aditiva sea una solución viable para la producción de piezas grandes. Una impresora 3D industrial para la fabricación de piezas funcionales.

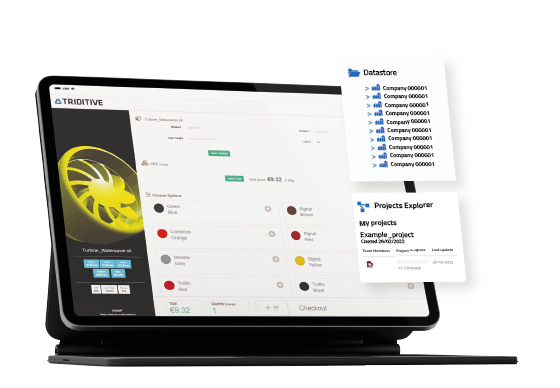

EVAM Software

Triditive ayuda a las organizaciones a automatizar y gestionar el flujo completo de fabricación aditiva desde una sola plataforma.

¿Te interesa la AMCELL 8300®?

AMCELL 8300® está diseñado y fabricado por Triditive. La fabricación aditiva automatizada es uno de esos cambios con el potencial de transformarlo todo. Una tecnología que permite escalar la producción exponencialmente.

Ponte en contacto

+34 984 200 010

info@triditive.com

Headquarters

Carretera Oviedo- Santander km8, 33199 Meres, Asturias

USA

1 Constitution Plaza, 2nd floor, Hartford, Connecticut, 06103

UK

Royal Arsenal Riverside London, SE18 6FR