Only in Spain, loss can rise to 16,000 million euros. According to the latest quarterly report from the Bank of Spain, the Spanish economy might lose up to nine tenths of GDP due to shortages in 2022. Further proving that the supply crisis puts the world economy in a hard spot.

While the demand for automobiles, machines and devices grows, the offer falls short, and the Spanish industry shakes before the possible loss. How can bottlenecks in the supply chain be overcome? Industry 4.0 makes a move and advances with additive manufacturing.

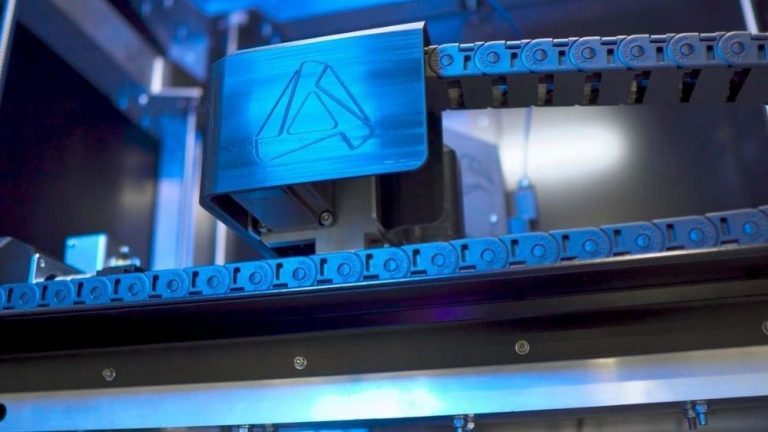

Contrary to extracting one part from a block of material, additive manufacturing starts from an idea. The machine adds the raw material to shape the component, eliminating waste and reducing the resources needed to manufacture it layer by layer. If in addition production is automated, checkmate. Additive manufacturing wins the game. And this is the case with successful companies like Triditive.

Additive manufacturing, the winning horse

We live in the age of immediacy: we want everything, and we want it now. But the excessive dependence on distant suppliers, added to the global transportation problems, is forcing consumption patterns to change. A change that we are not very willing to accept. This is where additive manufacturing and its proximity production approach come into play.

At an industry level, the benefits of additive manufacturing are well known: reduction of resources, production of parts on demand and prototyping at minimum cost, among others. But, at the consumer level, what can it do for us? From the point of view of local production and the resources management, costs are reduced, times are minimized, and sustainability is committed.

How to beat the supply chain crisis

The supply chain crisis has been hitting the Spanish industry ever since the beginning of the pandemic. The shortage of raw materials, and delays in orders from distant suppliers reinforce the need to change the production model.

The industry was in a hard spot, but companies like Triditive, a Spanish startup pioneer in automated additive manufacturing, have changed the rules of the game by betting on proximity production and the automation of manufacturing processes. This decision has been a complete success.

Technology for change

Triditive has won the GoHub Global Water Challenge Barcelona award thanks to EVAM, its cloud automation software. This software, which combines design and production on the same platform, enables the reduction of manufacturing costs, ensures just-in-time service and facilitates the supply of critical components.

Triditive’s work is not limited to cost reduction, it also shortens distances. These are the reason that made The Bank of America select it as one of the seven companies that are capable of creating technology for change, becoming part of its Innovator Spotlight program.

Triditive has been part of Santander X 100 since 2021, a global community of elite entrepreneurial projects. The project, promoted by the bank, supports the most innovative startups to connect with each other and access training and capital, with the intention of continuing to contribute to progress.

Learn the new rules of the game

However, it’s not all accolades. The leading automated additive manufacturing startup has continued to work to boost its industry and navigate the hurdles of the supply crisis. An example of this is the celebration of its 2nd Additive Manufacturing Forum on an industrial scale, in which international speakers from the sector participated, and where its new series of AMCELL machines were presented, the first to work with polymers and metals interchangeably.

Moving forward, Triditive will continue betting on industrial transformation and the comfort of its users to put an end to the problems of the industry. Checkmate the supply chain.