The breakdown of stocks in the supply chain causes losses of up to €4 billion each year in Europe. However, Industry 4.0, through Automated Additive Manufacturing, has the potential to solve the global supply problem.

The future of additive manufacturing depends on its automation. Through software, production and design come together on the same platform, simplifying the process. Companies gain autonomy, reduce production costs and take a chance on sustainability.

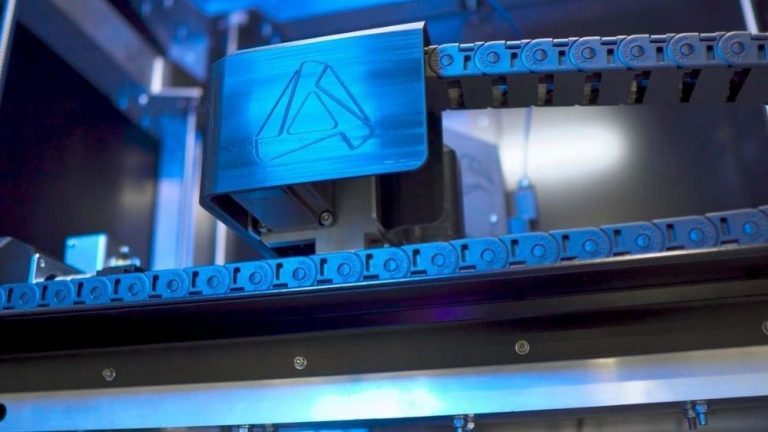

Triditive, the part that Industry 4.0 needs

The potential of additive manufacturing to solve the supply problem is one of the reasons that has led Triditive to be selected by the Bank of America as one of the 7 companies in the world capable of creating a technology for change.

Additive manufacturing is not only gaining importance in the management and dynamization of production and storage, it is also having a leading role in the digital and sustainable transformation of the industry. Two of the most demanded requirements by the Industry 4.0.

Digitalization of Industry 4.0

Because of the agility and technological capability that additive manufacturing is demonstrating in the most demanding circumstances, a recent HP study, in collaboration with 3dbpm Research, reflects that 63% of parts manufacturers plan to invest between €100,000 and more than €1 million in digitalization in the coming months.

Currently, “additive manufacturing is key to the production of industrial parts”, says Mariel, CEO of Triditive, “our focus is on the European market, which is one of the most powerful in this type of manufacturing”. Moreover, according to the study, the UK and German manufacturers are planning the strongest investments in digitalization and additive.

Automated additive manufacturing: the winning horse of industry 4.0

Commitment to automated additive manufacturing is essential for Industry 4.0. Manufacturing and design management from a single platform digitalizes storage. The production is done on demand and does not generate waste, achieving a zero stock in the manufacturing of parts.

In addition, thanks to the use of software and automation, the industries gain independence. They stop relying on the supply chain and distant manufacturers, betting on proximity production. Thus, sustainability is gained and shortages are avoided.

Sustainability, industry 4.0 and additive manufacturing

“In the world in which we move, sustainability has to be taken for granted, or at least turned to advantage as much as possible,”. One of the differential values of additive manufacturing on an industrial scale is precisely sustainability.

Compared to the subtractive manufacturing processes, in the additive the residues are reduced in a considerable way since only the material used for the part is required. “Building a better, more sustainable future with better conditions for workers depends on being able to take advantage of the technological innovation that allows us to reach it,”.