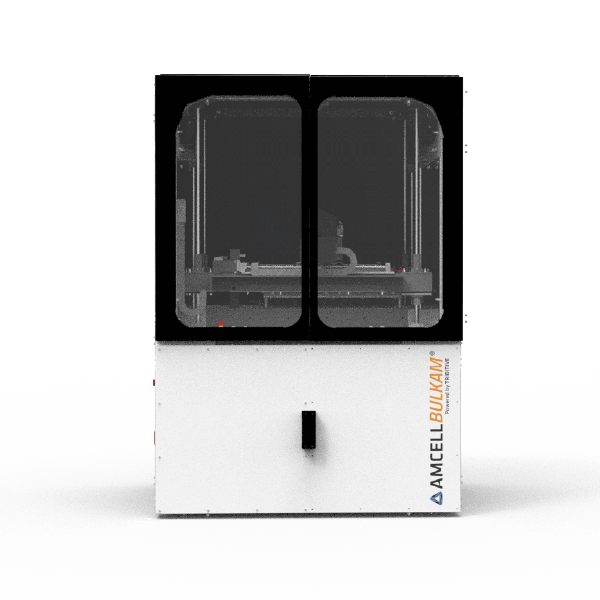

AMCELL BULKAM®

AMCELL BULKAM® is an industrial additive manufacturing cell to print medium complexity and precise final parts.

Manufacturing orders, process monitoring, feedstock control, smart environmental control, are just some of the features that makes AMCELL BULKAM® a robust platform for the production of large parts.

Large format parts with AMCELL BULKAM®

- Polymers

- Composites

- Metals

- High tolerance

- Large Format

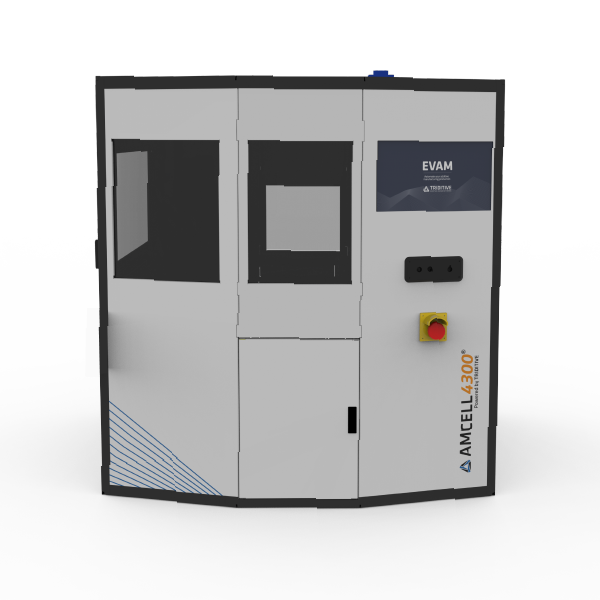

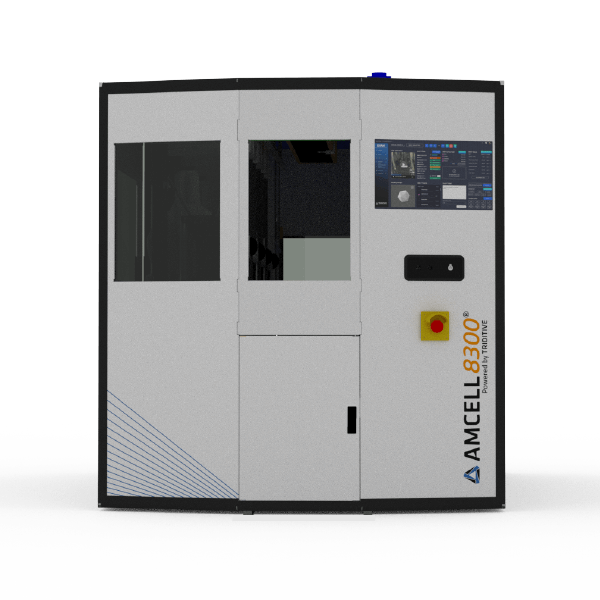

EVAM Software

- Centralized control and monitoring

- Feedstock smart control

- Production optimization

- Printer integration

- Build simulation

- Scheduling

- Shopfloor connectivity

- Quality and process monitoring

- Traceability

- Large format

- Build Simulation

Interested in AMCELL BULKAM®?

AMCELL BULKAM® is designed and manufactured by Triditive. Built for continuous operation in tough applications. Extremely robust components. A technology that allows to produce large parts.

High-performance large volume industrial 3D Printer.

Printing volume: 500x500x500 mm.

Software-controlled workflow and process monitoring

AMCELL Bulkam® includes EVAM Software®, the most advanced

production control and remote monitoring solution.

Our Materials

We print in a wide range of materials for your convenience

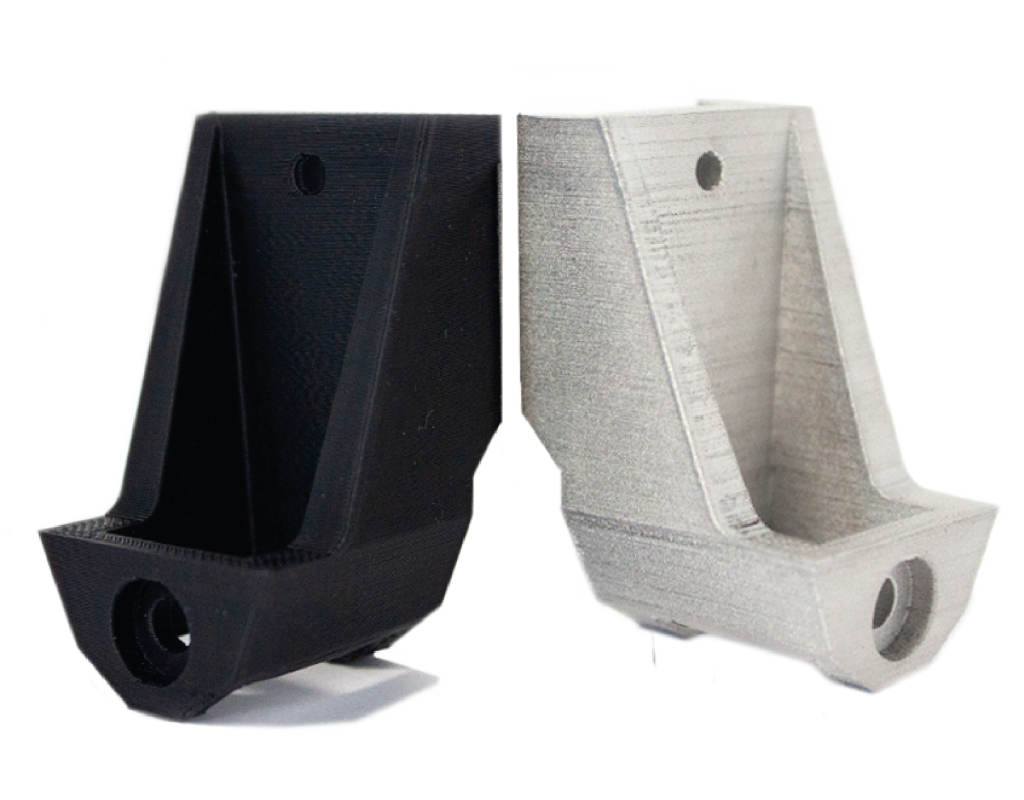

Metals

The advantages of metal 3D printing are that it has the potential to be more cost-effective, especially at low volumes, for parts that are difficult to machine due to their complexity or material.

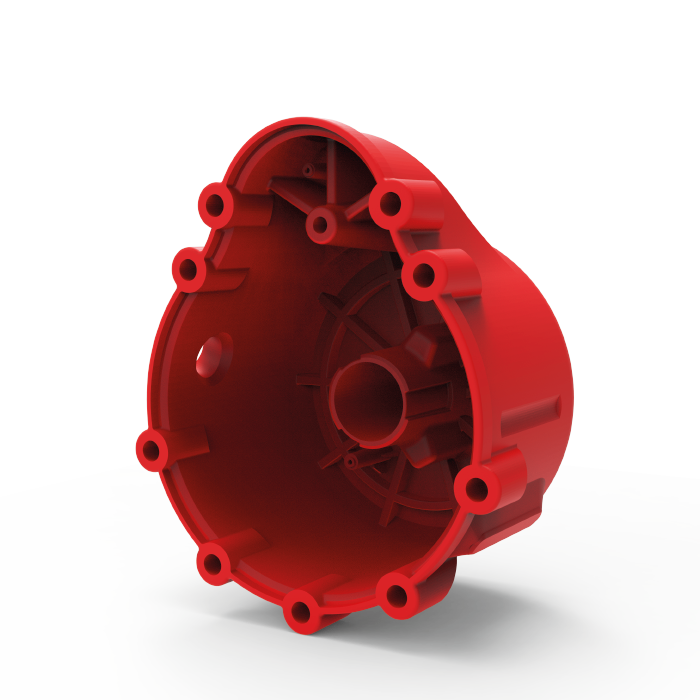

Polymers

We can produce functional and complex polymer parts with the strength, dimensional accuracy and finish quality needed for high-volume production.

Composites

Composite materials are typically used to improve the strength, stiffness, heat resistance, and durability of traditional 3D printable parts.

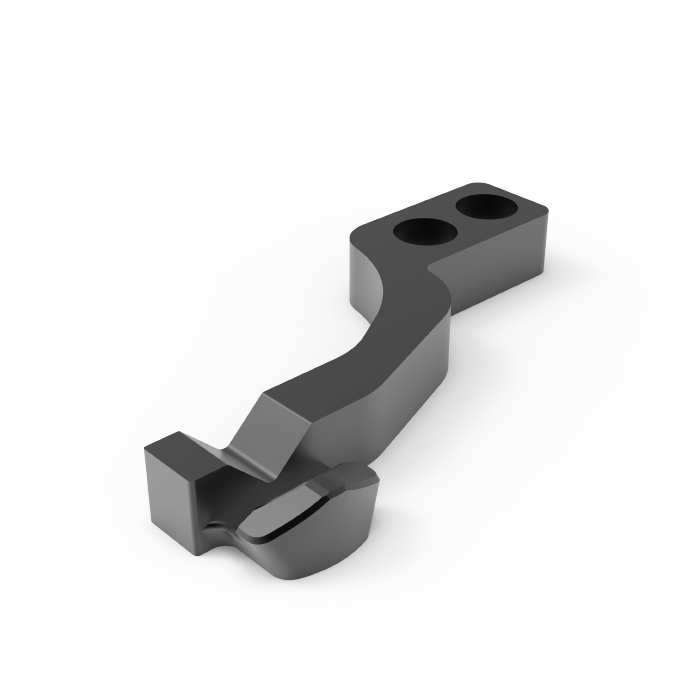

AMD Technology in Metals

Automated Multimaterial Deposition® (AMD) is an additive manufacturing process. The main innovation that incorporates our technology is automation and its capability to manufacture parts in polymers, composites, and metals, even at the same time.

Technical Specifications

Technical Information

- AM Technology: AMD

- Maximum printing height: 500mm

- Maximum printing area: 500x500mm

- Extruder system: Direct extrusion

- Nozzle diameter: 0.4 - 1.2 mm

- Minimum layer height: 50 μm

- Build chamber: Heated with temperature control, Bofa® filtering system

- Temperature Build chamber: 60 ªC IR Heating System

- Weight: 350kg.

- External dimensions: 1,059x 1,32 x 1,96 m.

Manufacturing Platforms

- Platform feeding system: Manual

- Build platform: Heated up 130 ªC

- Build platform material: Vitroceramic glass (customizable)

- Build platform calibration: Automatic

- Final parts storage: Manual

Manufacturing Materials

Polymers: ABS, ASA, CPE, HIPS, IGLIDUR I150-PF. PA,PC, PETG, PLA, TPU, VYNIL.

Composites: PA+ARAMIDE, PA+CF, PC+ABS, PC+PBT, CPE+CF.

Metals: SS316L, SS17-4PH, INCONEL, TITANIUM.

Interested in AMCELL BULKAM®?

AMCELL BULKAM® is designed and manufactured by Triditive. Built for continuous operation in tough applications. Extremely robust components. A technology that allows to produce large parts.