For a project to exist, it is almost indispensable that there is a set of parts (internal or external) that have specific characteristics assigned to them.

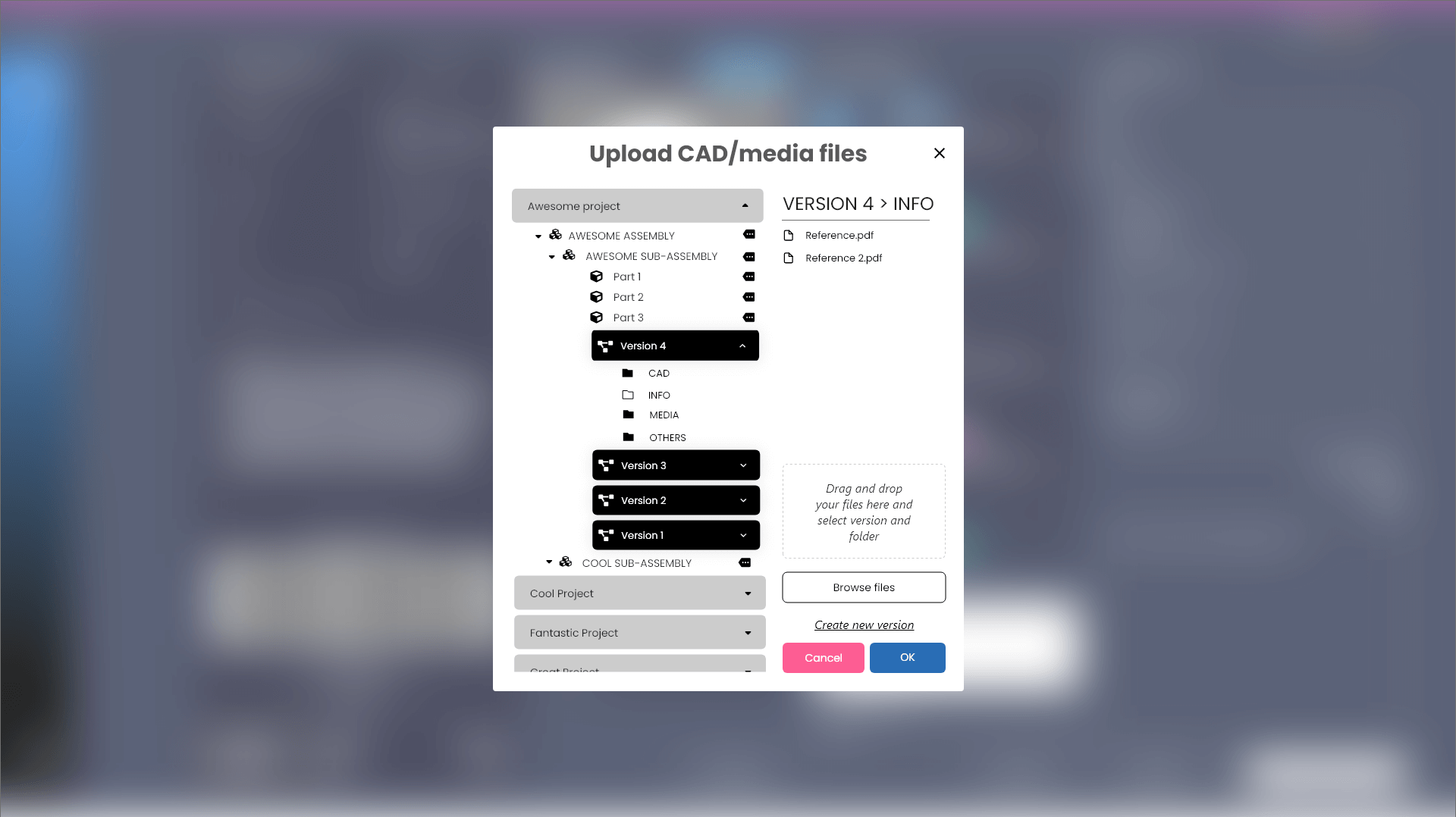

These characteristics are detailed in this section as well as the related files that make their existence possible.

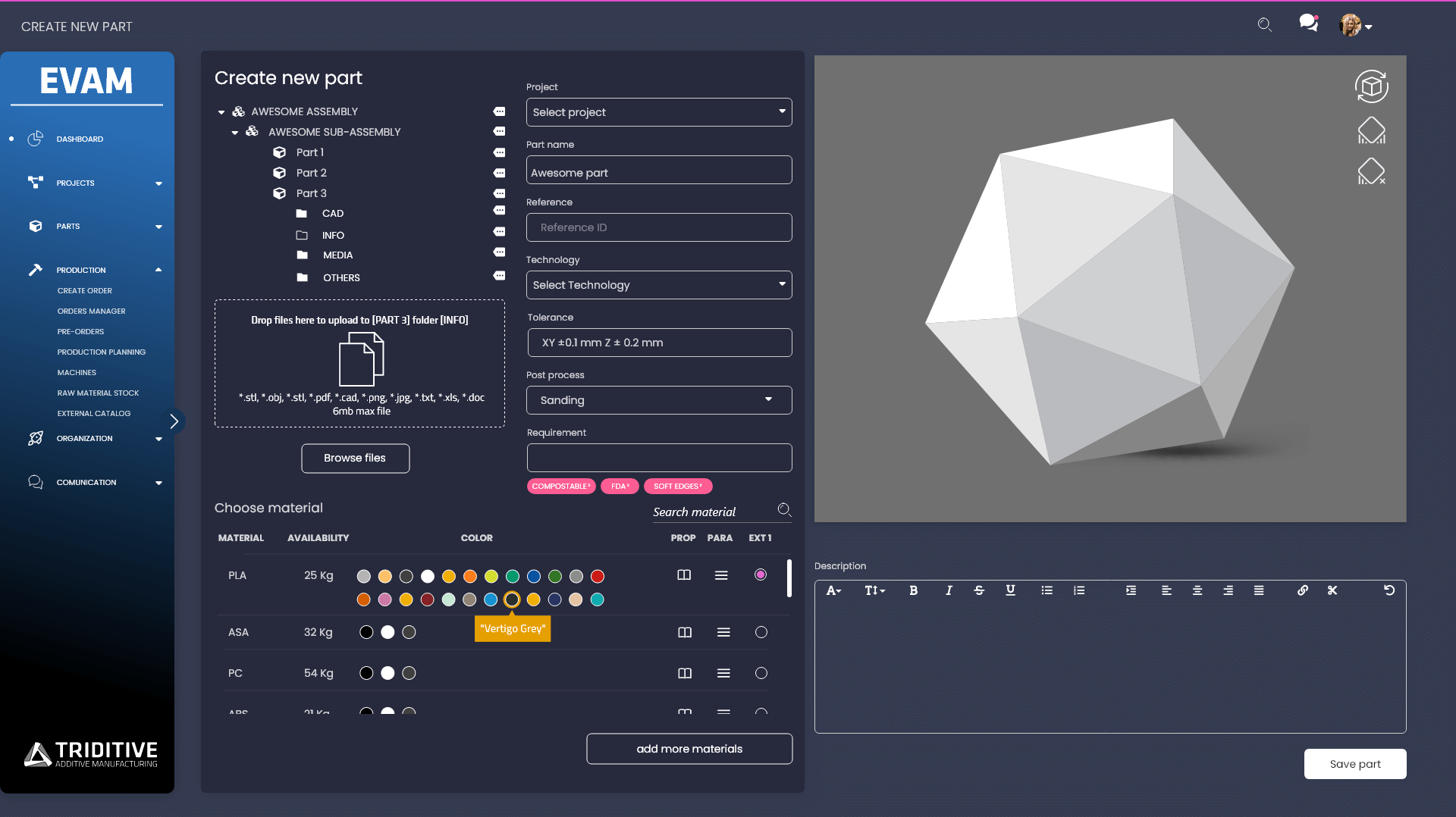

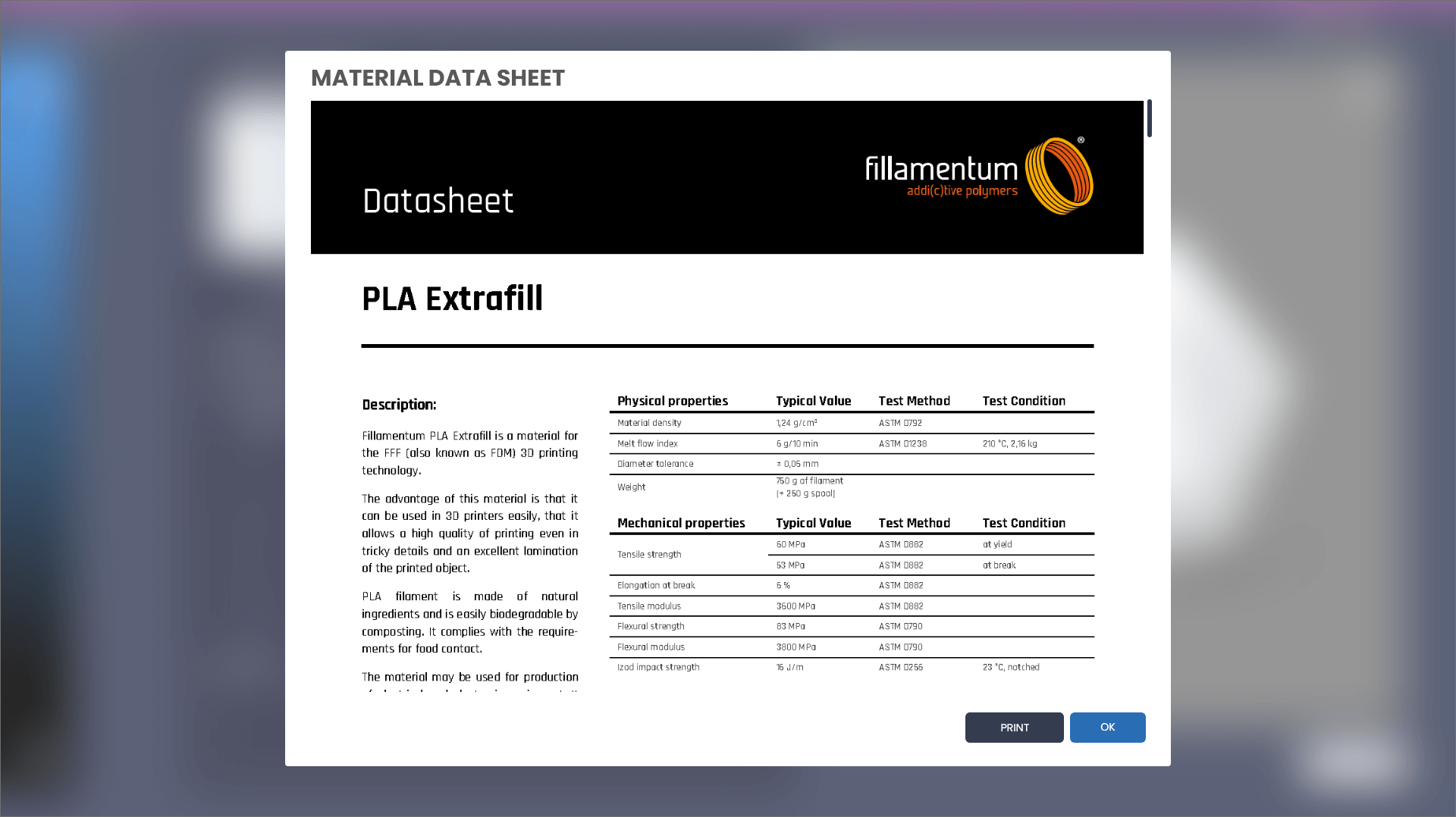

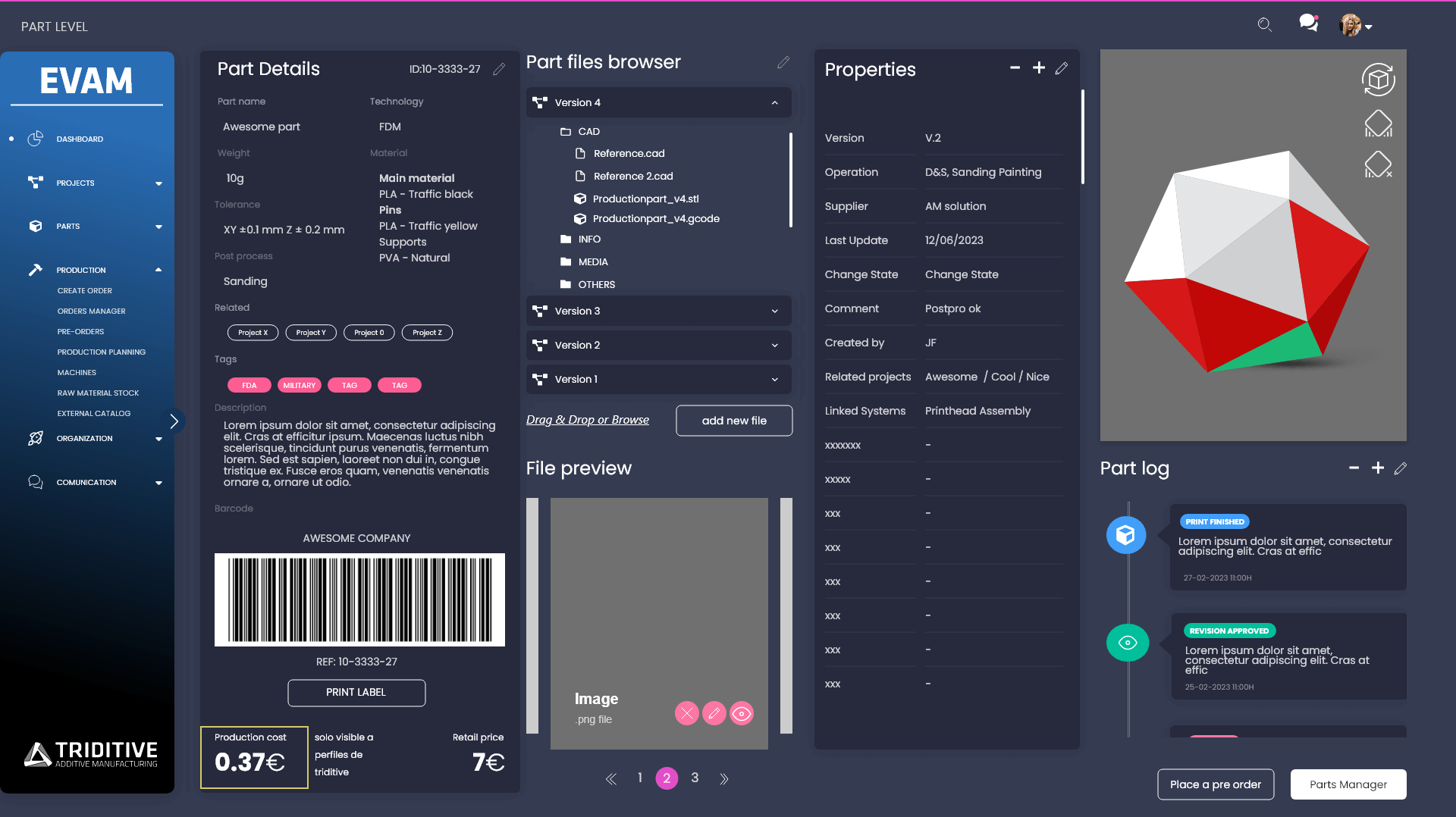

When registering a part we must assign specific values that can be edited later if necessary.

These values are:

- Project

- Part name

- Reference ID

- Manufacturing technology

- Tolerance

- Post-process

- Requirements

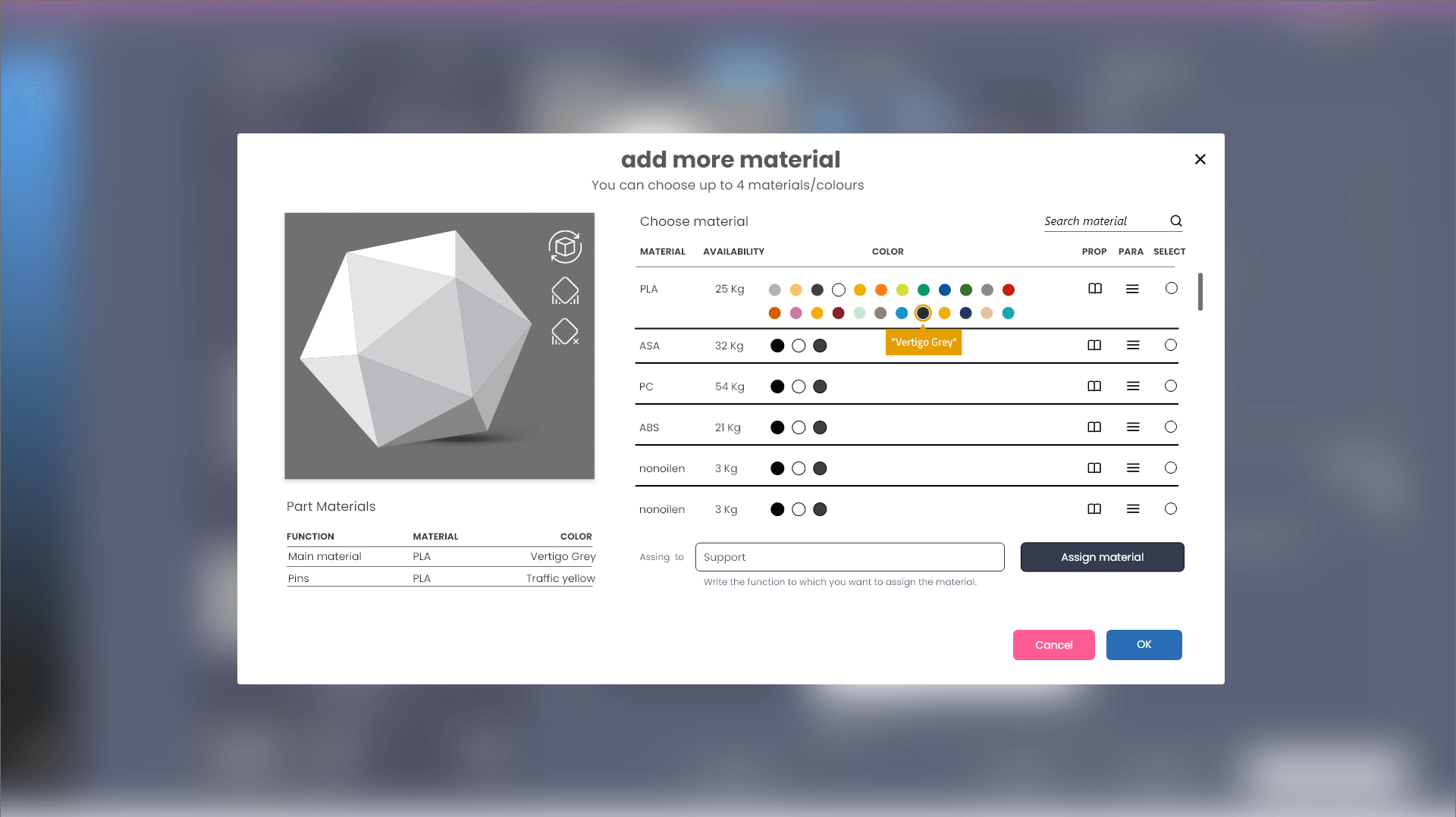

There are some cases, in which the printed parts (depending on the chosen technology) may require two or more materials, so we can indicate them by clicking on the “add more material” button, this will open a modal window that will make it possible to assign materials to different sections or functions of the part.

In the detailed view of the parts we can know all the information related to it, the same information that was entered when registering it, but also information that has been generated as it progresses in its life cycle.

When we are manufacturing a part or assembling an assembly, situations arise and these are reflected in the log (which is generated automatically and manual entries) and the log of tickets assigned to that part.

Also, as in projects, it is important that we have all the information of processes and suppliers involved in the creation of the element.

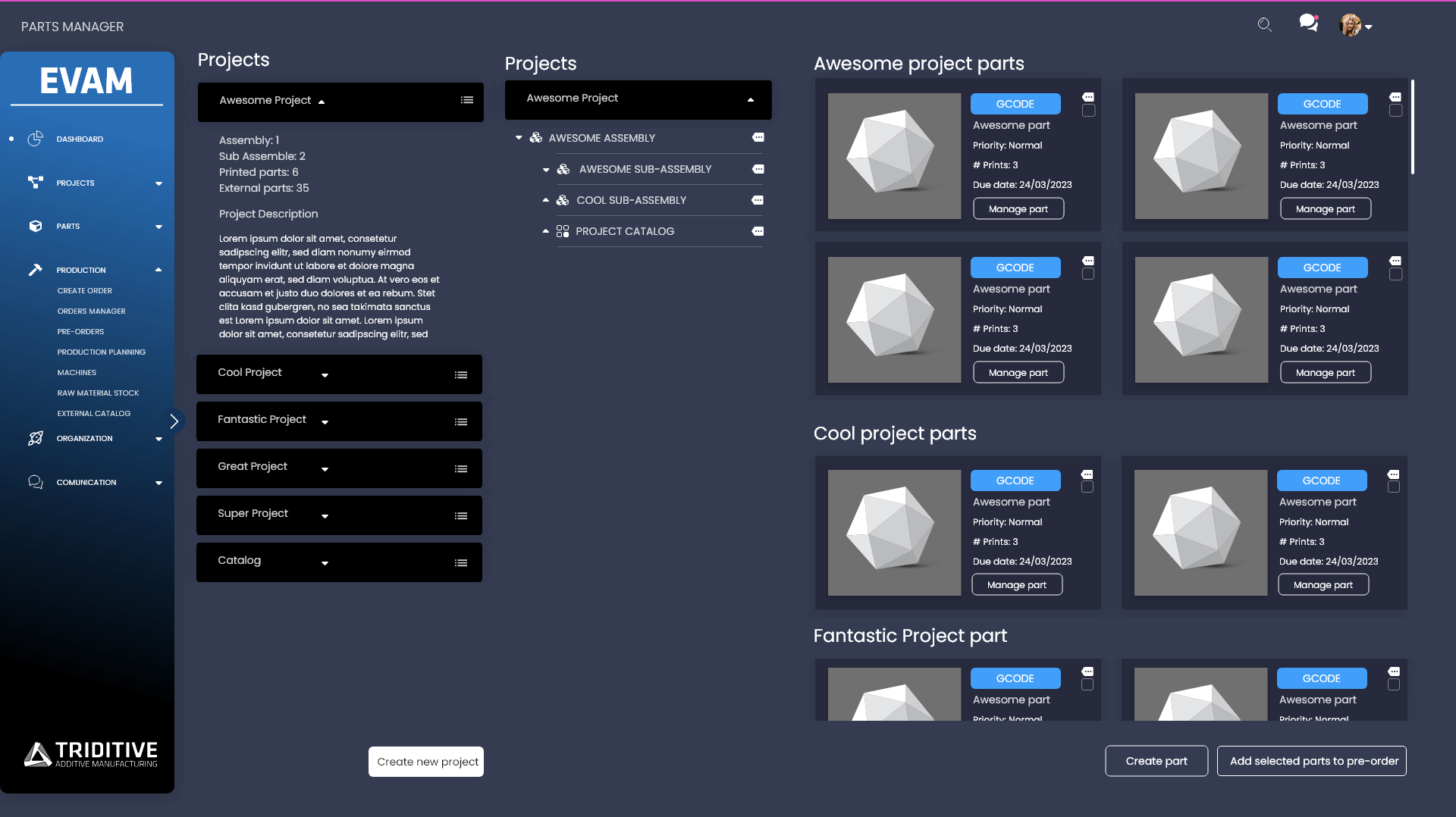

Through the parts manager we can know to which projects each part is assigned, as well as know in which assemblies it plays a role.