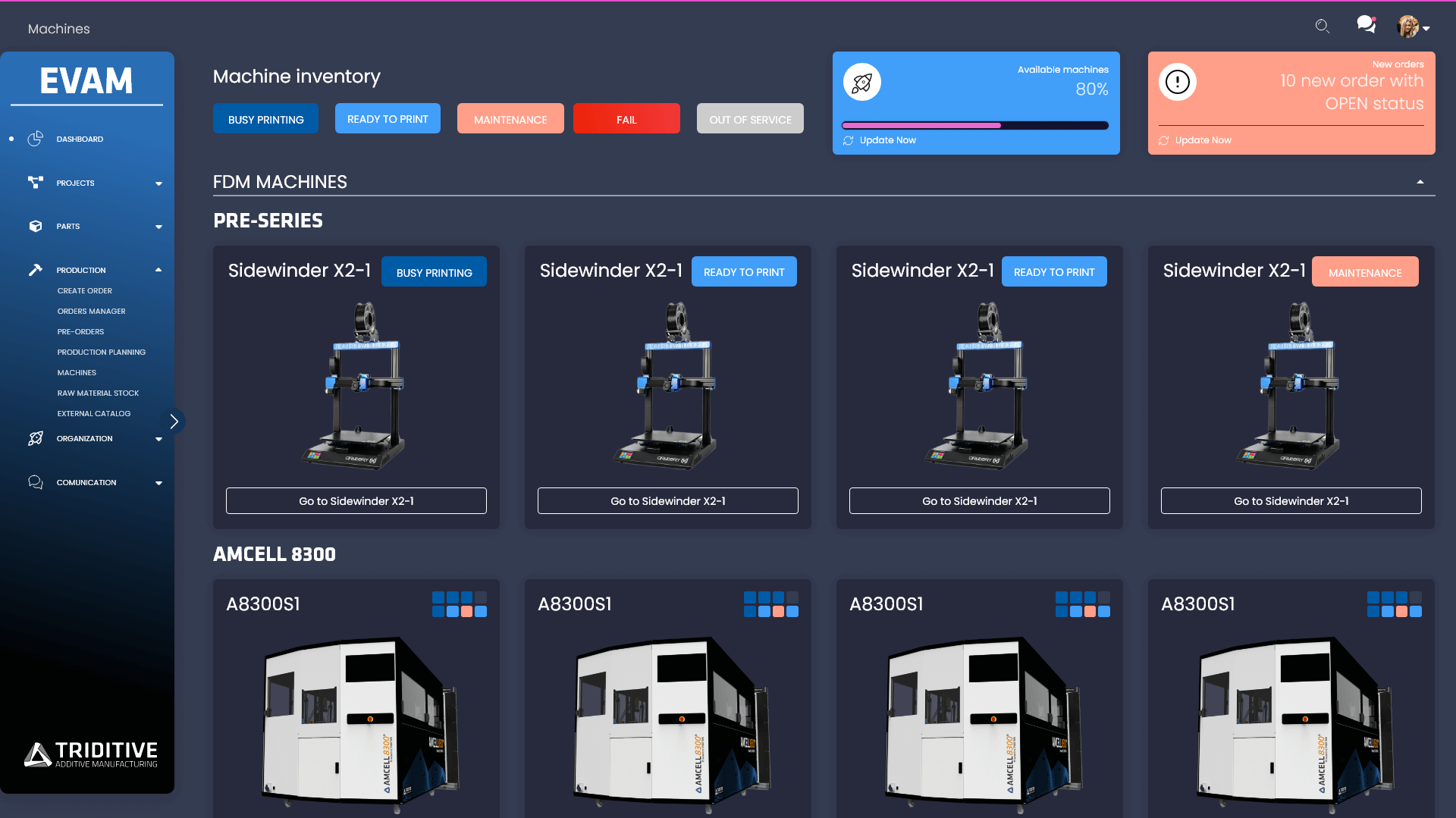

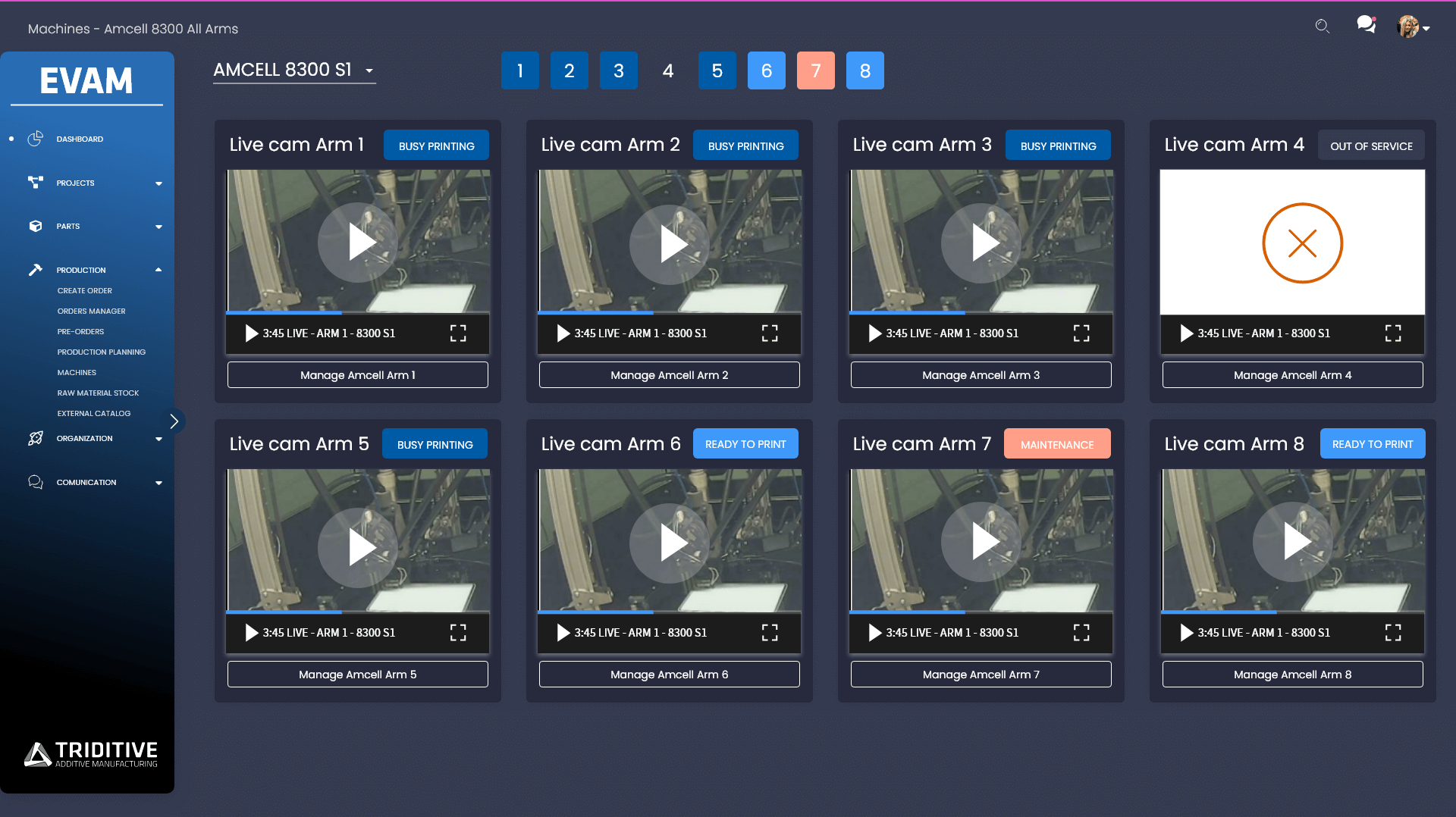

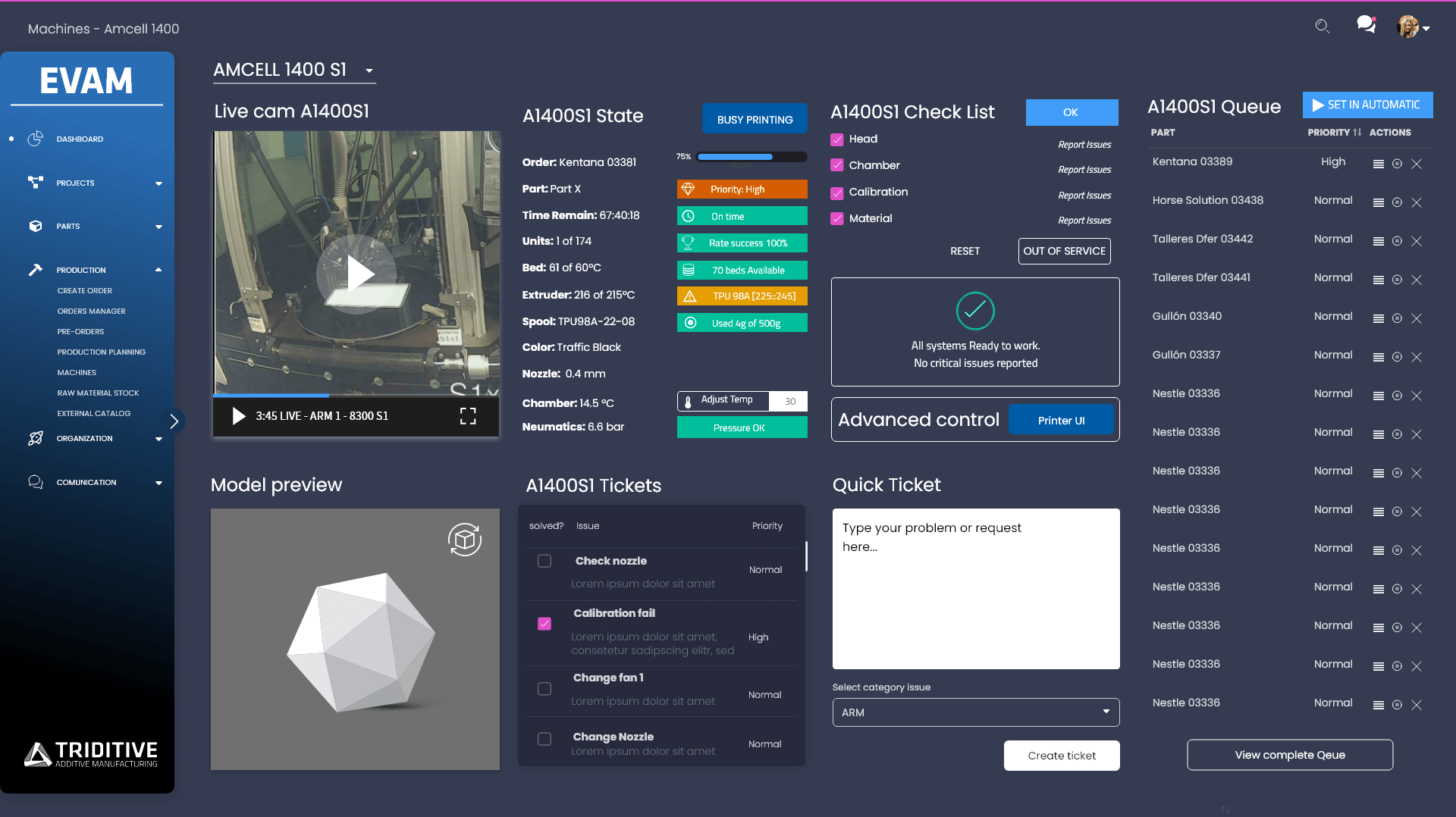

From the machines section we can know the real-time status of each machine used for the production of parts through additive manufacturing.

EVAM integrates different technologies and machines, own and third party.

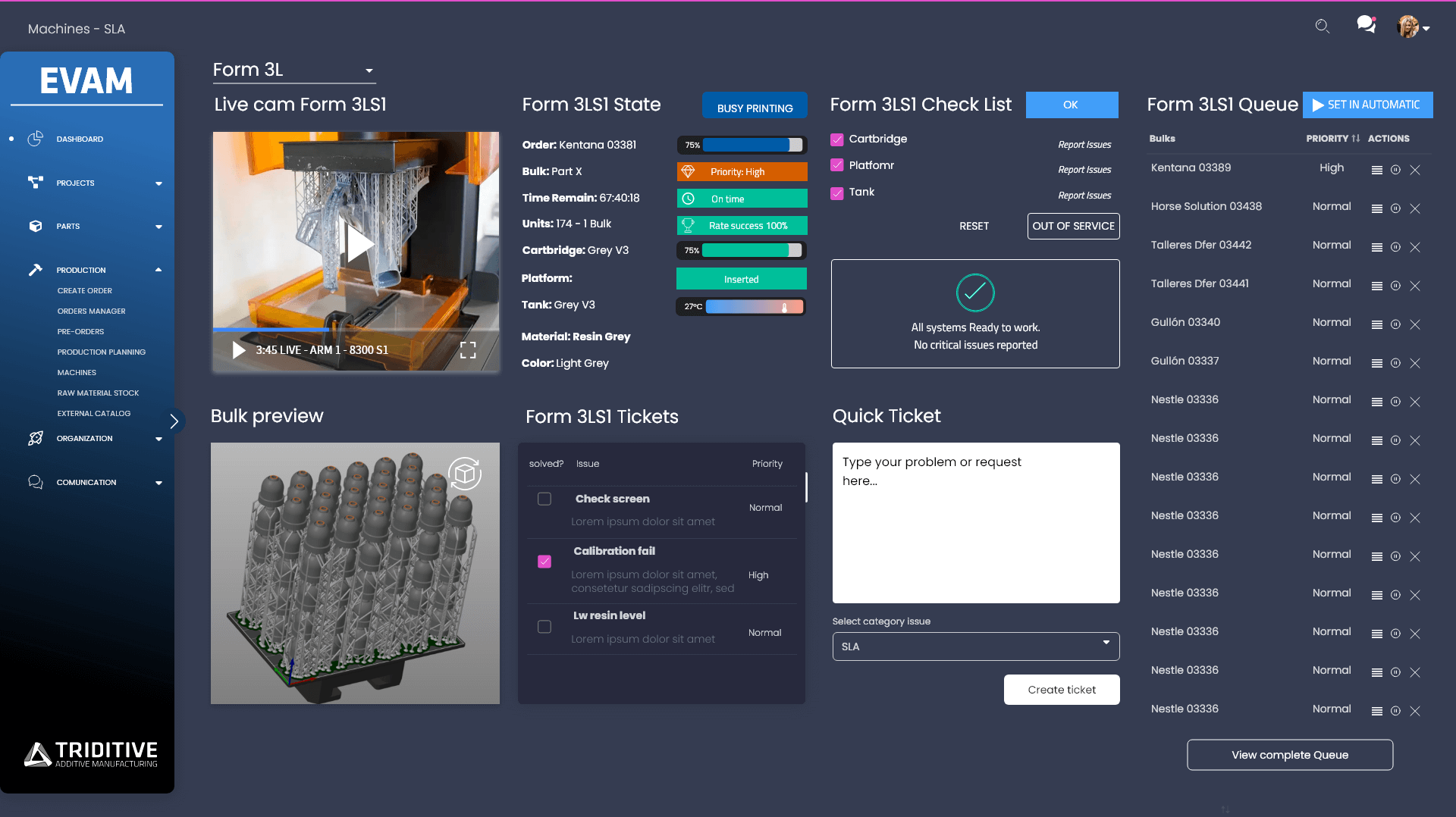

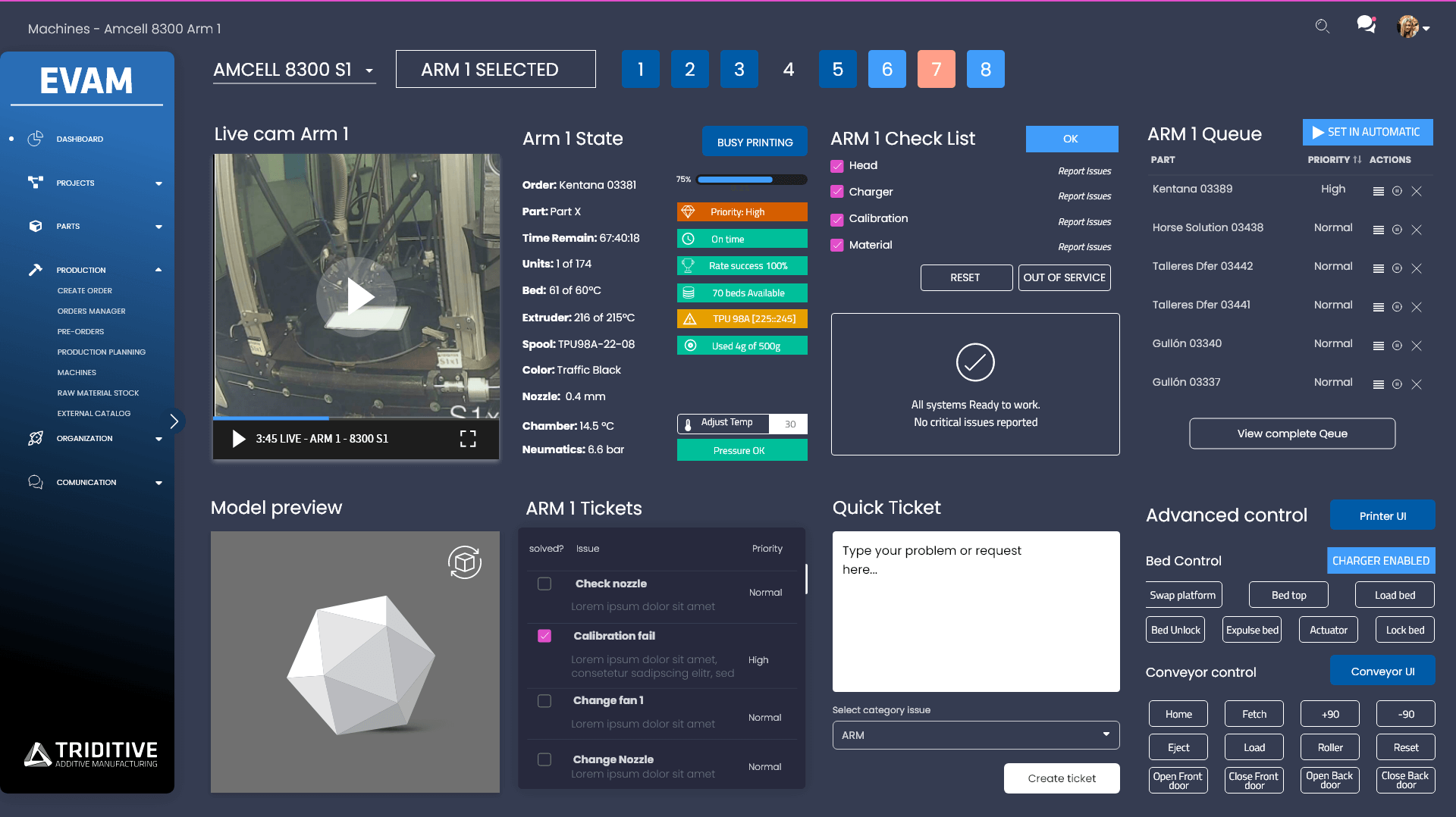

In the specific section of the selected machine we will be able to access the information that will allow us to execute it.

We have a camera that allows us to visualize the current status of the arm, this makes possible the execution of the machine remotely.

We have a checklist to verify the correct functioning of critical systems and to establish if the machine is in condition to face the productive tasks.

- Nozzle

- Chamber

- Material

- Calibration

- Platform

In addition to the pre-flight check we have the display of the print parameters inherited from the gcode such as:

- Time remaining

- Units

- Bed temperature

- Extruder temperature

- Material

- Color

- Nozzle diameter

- Chamber temperature

- Pneumatic pressure

- Platform status

- Tank temperature

- Dust Level

- And much more depending on the technology

Other functionalities that we have in the machine management panel are:

- Part or Build Preview

- Print Queue

- Machine Specific Tickets

- Quick ticket form