TRACED®

TRACED® is an automatic storage module to keep traceability and store under safe the finished printed parts.

It is integrated with EVAM Software® for factory connectivity and factory floor integration.

AUTOMATION & TRACEABILITY WITH TRACED®

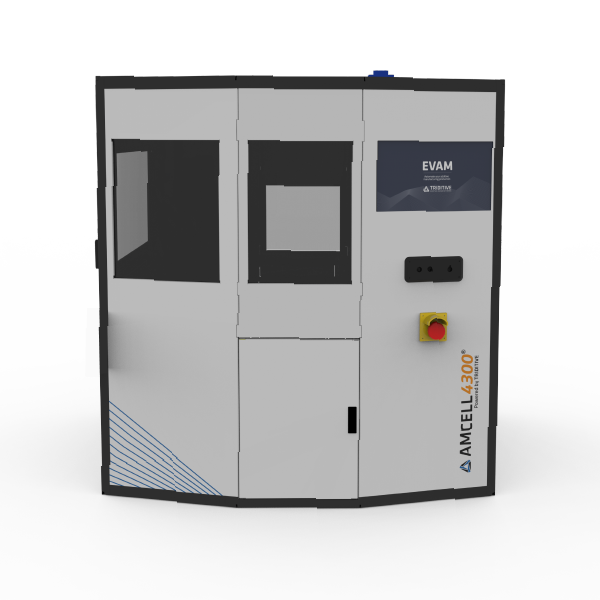

EVAM Software

- Centralized control and monitoring

- Feedstock smart control

- Production optimization

- Printer integration

- Build simulation

- Scheduling

- Shopfloor connectivity

- Quality and process monitoring

- Traceability

- Mass production

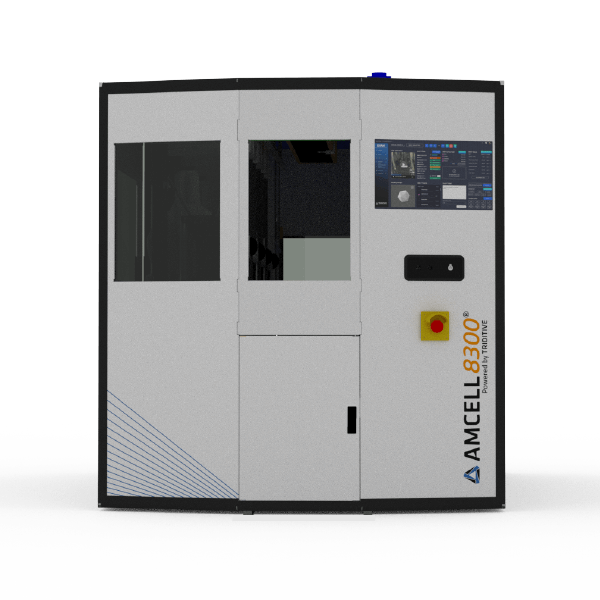

TRACED ® + AMCELL® the perfect match

Each column represents a group of slots (can be increased up to 8). Each slot can hold up to 5 platforms.

Tracking information such as material, order number, customer information, production date, postprocessing, and shipping details is accessible at any time through EVAM® platform.

Interested in TRACED®?

TRACED is designed and manufactured by Triditive. Automated Additive Manufacturing is one of those changes with the potential to transform everything. A technology that allows to scale the production exponentially.

Storage Module Specificactions

Unit

- Height: 3000mm

- Depth: 1560mm

- Widh: 2000mm

Carrier

- Height: 420mm

- Depth: 300mm

- Widh: 300mm

Capacity

- Finish jobs capacity: 80 to 160 units

Interested in AMCELL®+TRACED?

AMCELL and TRACED designed and manufactured by Triditive. Automated Additive Manufacturing is one of those changes with the potential to transform everything. A technology that allows to scale the production exponentially.