Metal Binder Jetting

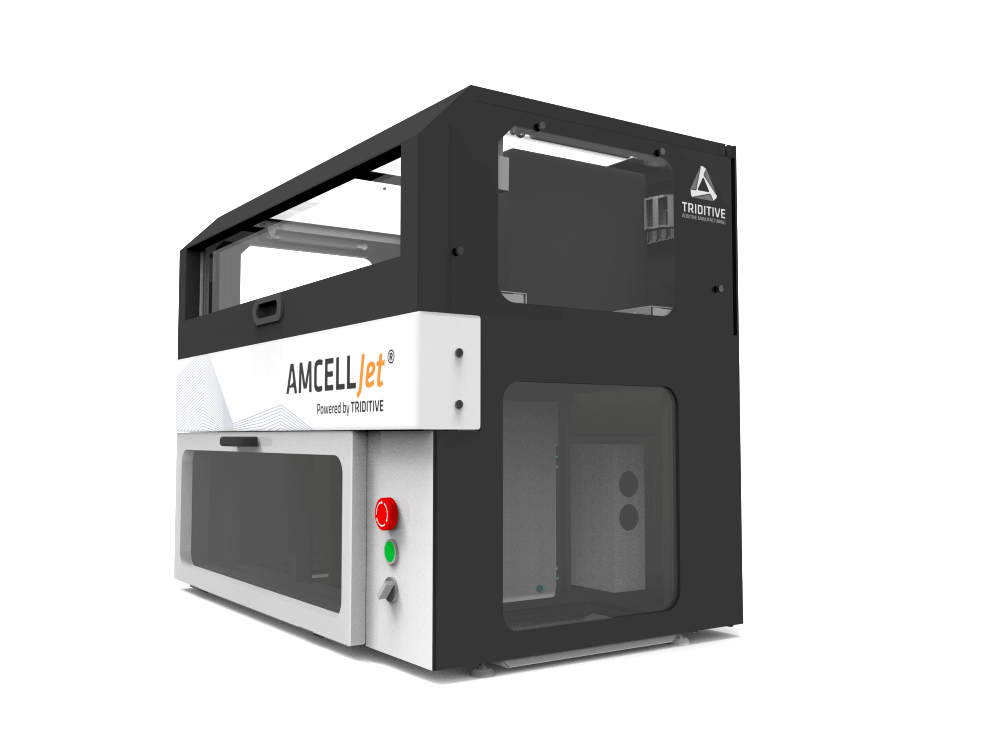

Amcell Jet®

AMCELLJet® is a machine designed for the production of small and medium-sized metal parts, for highly demanding application, allowing to reduce the cost per part by 10 times compared to SLM additive manufacturing technology.

Interested in AMCELL Jet®?

AMCELL Jet is designed and manufactured by Triditive.

The equipment works by depositing metal powder layer by layer, after finishing the printing process the parts are sintered in a post-process.

Key Features

Cutting Edge Technology

Binder Jetting is a high resolution metal printing technology that allows high complexity in the printed parts as is a support free technology.

Easy Integration

Software and hardware environment can be integrated into existing manufacturing lines.

Affordable

Binder Jetting is the most efficient and cost effective way to print metal parts.

Technical Specifications

Technical Information

- X/Y Resolution: 600 dpi

- Layer Thickness: 50 μm

- Printing Volume: 216 x 140 x 80 mm

- Max. Printing Throughput:1000 cc/hr - 61in3

- External Dimensions: 900 x 500 x 700mm

- Powder Suply System: Box to box supply system

Manufacturing materials

Polymers: ABS, ASA, CPE, HIPS, IGLIDUR I150-PF. PA,PC, PETG, PLA, TPU, VYNIL.

Composites: PA+ARAMIDE, PA+CF, PC+ABS, PC+PBT

Metals: SS316L, SS17-4PH, INCONEL, TITANIUM.

- Powder Tray: Single powder Tray

- Printhead: 2x Piezoelectric printheads

- Weight: ~100Kg

- Temperature Range: 20 ~ 25℃

- Humidity Range: 40 ~ 60%

- Model Tray: Removable

- Powder Spreading: Up to 10 ips / Up to 750 rpm / Spreading Roller Diameter: 30mm