In 2021 we are witnessing a lack of materials in the line of supplies worldwide. It is essential to take on the challenge for the global economy. This issue is an unmistakable symptom of the need for the industrial area to develop urgently. And the manufacturing industry in particular.

Five reasons why Automated Additive Manufacturing may drive the industrial revolution:

1. Being a change agent in the economical, social and environmental future

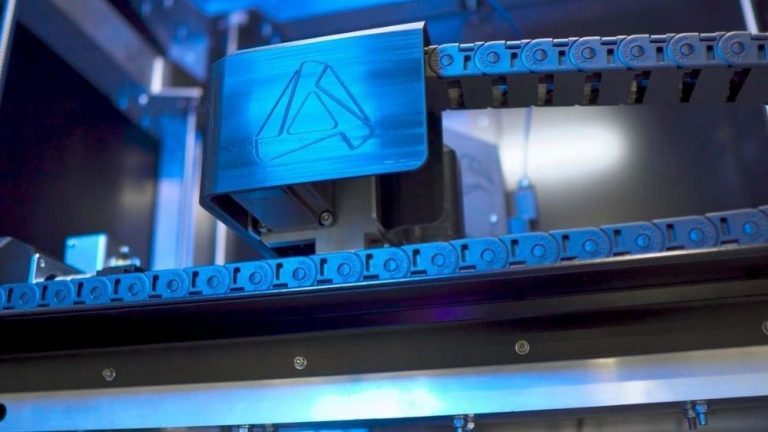

We are living in an era marked by the energy crisis, which is affecting the entire planet. Being part of Industry 4.0 means addressing this issue from an economic and environmental perspective. Technologies such as AMCELL 1400 and 8300 enable the simplification of the distribution chain, thus optimizing the consumption of strategic resources.

2. The role of the AM in the future of the planet

We frequently hear people talking about “crises” regarding the evolution of the population. The population of the Earth has tripled between 1950 and 2010 and, in case predictions come true, it might quadruple in 2050. Today there are about 7,5 billion people in the world. And it is estimated that it will rise up to 10 billion.

3. The balance in the productive process

The balance between production, demand, population and geographical distribution of manufactured goods, will become an economical issue that market fluctuations won’t be able to solve. That is why we believe that it is a much deeper problem. A question about environmental and quantitative viability. Taking into account the present business management environment, it won’t be possible to satisfy the global demand of manufactures. And we are not talking about 2050, but next year.

4. Prominence in the digital transformation of the industry 4.0

Additive Manufacturing is not only gaining importance in the management of the manufacture and storage, but also is taking a leading role in the digital and sustainable transformation of the industry, two of the most important aspects for the industry 4.0. “We have such a flexible technology that almost any product can be created locally, of nearly any material.-“ has stated recently Mariel Diaz when interviewed by 3D Printing Industry. In order to develop a sustainable industry in the future, the AAM multiplies the efficiency and the volume of production, of dozens to thousands of manufactured items, with a high level of autonomy and a less workload.

5. The Flexibility of the automation

The AAM is a very flexible technology that can make, locally, almost any product, of almost any material, and in a sustainable way. But, as Mariel has also pointed out, “in the world we move, sustainability must be assumed or, at least, favoured to the fullest”, since the automated additive manufacturing is cleaner than the present processes. Numbers do not lie. If we compare it with the subtracting processes, waste is reduced considerably as it will only require the material for the item itself.

A better and more sustainable future, with better working conditions, depends on our ability to take advantage of technology and innovation, in order to achieve it.

The potential of Triditive Technology to solve problems, has led Triditive to be selected by the Bank of America as one of the 7 companies in the world, able to create a technology for the change. This acknowledgment makes us go on displaying our technology to the world. Triditive is in the spotlight in the USA, and that gives us a good level of exhibition, which confirms we are on the right track and accelerate our international expansion. We continue working to change the industry and hope AAM will be part of the next industrial revolution… Something that is already happening.

If you want to know more about Automated Additive Manufacturing, we recommend you read this article